Jaw Crushers for Sale Unleashed: Finding Effectiveness in Every Sale

Jaw Crushers for Sale Unleashed: Finding Effectiveness in Every Sale

Blog Article

Effectively Recycle Materials With the Power of a Jaw Crusher

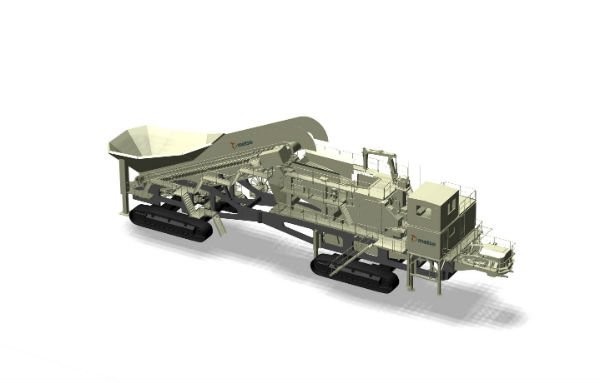

One such service is the utilization of a jaw crusher, a powerful equipment that has revolutionized the reusing procedure. In this discussion, we will certainly dive right into the advantages of a jaw crusher, the materials ideal for crushing, the considerations for recycling operations, and valuable maintenance and safety and security ideas. Allow us explore just how a jaw crusher can play a pivotal function in successfully recycling materials.

Advantages of a Jaw Crusher

The advantages of a jaw crusher are numerous and make it an important tool for efficient recycling of products. The jaw crusher's layout permits for big items of product to be squashed down to a smaller sized size, resulting in a more manageable and consistent product.

Another advantage of a jaw crusher is its high ability. jaw crushers for sale. These makers are developed to deal with large amounts of product, permitting efficient handling and boosted efficiency. This is especially important in recycling operations, where huge quantities of product require to be refined rapidly

Products Ideal for Crushing

Jaw crushers are flexible equipments that are frequently utilized in mining, construction, and demolition markets to squash products right into smaller sized dimensions. These materials can hold up against the stress put in by the jaws of the crusher, resulting in reliable squashing.

One more important consideration is the abrasiveness of the material. Products such as limestone, dolomite, and sandstone are understood to be rough and can cause too much endure the jaws of the crusher. With correct upkeep and the usage of wear-resistant products for the jaw plates, these materials can still be properly crushed.

In addition, the dimension and shape of the product also play a duty in establishing its suitability for crushing. Jaw crushers are especially effective in crushing huge, tough, and irregularly designed materials. They may not be as reliable in squashing smaller sized, softer, and much more consistent products.

Recycling Procedure Considerations

When thinking about reusing operations, there are a number of key aspects to take into account. Primarily, it is important to evaluate the type and amount of materials that will be refined. This will figure out the size and capability requirements of the jaw crusher that will be used in the recycling procedure. In addition, it is crucial to consider the preferred final product dimension. Various crushers have different capacities in regards to lowering products to a certain size array. Consequently, recognizing the end product needs is crucial in picking the appropriate jaw crusher for the reusing procedure.

Another important factor to consider is the functional cost site link of the recycling operation. This consists of the expense of getting and maintaining the jaw crusher, as well as the price of electrical energy and other resources required for its procedure. It is necessary to choose a jaw crusher that uses high efficiency and low operating prices to guarantee the success of the reusing procedure.

Upkeep and Safety Tips

Thinking about the vital nature of upkeep and safety in a reusing procedure, it is crucial to execute reliable methods to make sure the smooth functioning of this link the jaw crusher and secure the health of workers involved. Regular upkeep is critical for the jaw crusher to operate at its peak performance. This includes checking the equipment regularly, examining for any kind of signs of deterioration, and resolving any kind of issues without delay. Lubrication is also important to protect against rubbing and overheating, so it is necessary to comply with the supplier's standards for oiling and oiling the device. jaw crushers for sale.

Furthermore, security precautions should be purely followed in order to stop accidents and injuries. All workers running the jaw crusher need to obtain appropriate training on its usage and safety procedures. Protective equipment, such as construction hats, shatterproof glass, and ear defense, ought to be used whatsoever times. The workspace must be kept clean and complimentary of debris, and any possible dangers should be addressed right away.

Regular assessments and maintenance timetables should be developed to ensure that the jaw crusher is working ideally and securely. By adhering to these upkeep and safety ideas, recycling Click This Link operations can take full advantage of the efficiency of their jaw crushers while focusing on the health of their personnel.

Maximizing Effectiveness With a Jaw Crusher

It is essential to match the jaw crusher's capacities to the particular needs of the material being refined. Keeping track of the crusher's efficiency through normal measurements and information evaluation can help recognize opportunities for improvement and maximize the crusher's procedure. By applying these approaches and methods, drivers can optimize the effectiveness of a jaw crusher and accomplish better general performance in their reusing operations.

Verdict

In this discussion, we will dive right into the benefits of a jaw crusher, the materials ideal for crushing, the considerations for reusing operations, and important upkeep and safety and security suggestions. Allow us check out just how a jaw crusher can play a critical function in successfully recycling materials.

Keeping an eye on the crusher's efficiency via regular measurements and information evaluation can aid identify opportunities for enhancement and enhance the crusher's procedure.In verdict, a jaw crusher uses countless advantages in efficiently recycling materials. In general, the use of a jaw crusher shows to be an efficient option for reusing products.

Report this page